459.000 hours of operation

Ten years continuous operation of UR12 at Hot Roll

Ten years continuous operation of UR12 at Hot Roll

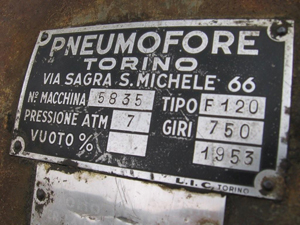

One F120 air compressor with 7 bar was manufactured in 1953 and has been running in a local steel plant round-the-clock until 2007. At that time it represented a solution to produce compressed air with a revolutionary technology as it replaced a piston compressor with inter cooling. Finally, after 54 years of operation, a new Pneumofore unit was installed.

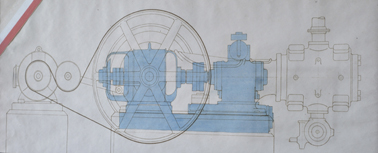

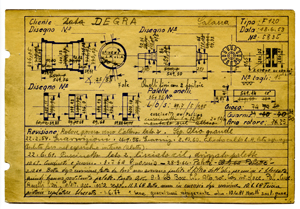

The air compressors manufactured since 1923 in by Swiss engineers were the world's first, single stage, rotary air compressors. The mission of Pneumofore was to introduce rotary vane technology to replace piston technology. As shown in the drawing on the below, the aim was to have much lower space requirements, less moving parts, lower rotation speed, easier handling, less maintenance and all over higher efficiency. With 750 rpm, the F120 had no mechanical stress and managed to compress air from atmospheric pressure to 7 bar, without inter cooling. The direct coupling was a key feature, no gear boxes were required 85 years ago. The active sealing of piston compressors is found in vane compressors too, as the function of the piston rings correspond to the one of the vanes.

If the mentioned F120 air compressor, a thermodynamic machine with energy conversion from electric to pneumatic, had been a car engine running at average 100 km/h, for 8.500 h/year, it would have done 46 million km, thus 1.146 times around the world's equator, which measures 40.055 km. Such extraordinary reliability over decades was not an exception, when compared to piston technology, which is still used today as highly evolved machinery in every car engine. The simple geometry of piston and vane machinery makes overhaul operations easy, a lathe is sufficient to execute also major repair jobs. This explains why some Pneumofore rotary vane compressors are installed in remote areas, from the heart of Brazil to the desert of Libya, where OEM independence is crucial, where only heavy industrial machinery survives over decades, while modern, sophisticated, high tech electronic devices frequently fail without chance of service.

Unfortunately, the most popular compressor technology today is screw. The geometry of a screw makes repair jobs impossible, after 50.000 h of operation the screws usually need replacement, causing costs up to 50% of the initial price. Screws have no active sealing, most are driven by a gear box and there are at least 6, if not 10, bearings where piston and vane compressors need only 2. More moving parts increase the risk of any failure, the simplicity of reliable and durable vane compressors was surpassed by the fashionable, but in terms of Life Cycle Cost very expensive screw compressors, which only have a low purchasing price tag. Pneumofore is anytime and anywhere ready to compare the efficiency of its machinery with any alternative technology, but with a sight over decades, not few years only, as the resources of our planet are limited.

November 2009