Vanetech News

K SeriesRotary Vane Air Compressors

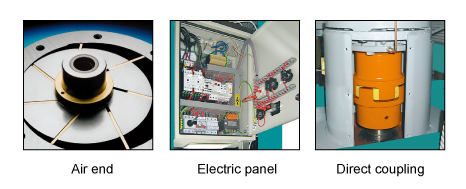

Main Features

- Single-stage rotary vanetechnology represents the simplest and most reliable solution for compressed air production.

- Constant performancethanks to active sealing and few moving parts subject to wear.

- Two bearingsensure limited friction in order to guarantee negligible power loss and low maintenance.

- Direct couplingto 4-pole motor at 1.450 rpm for 50 Hz, with IP55 protection for a low rotation speed and long durability, same also for 60 Hz operation.

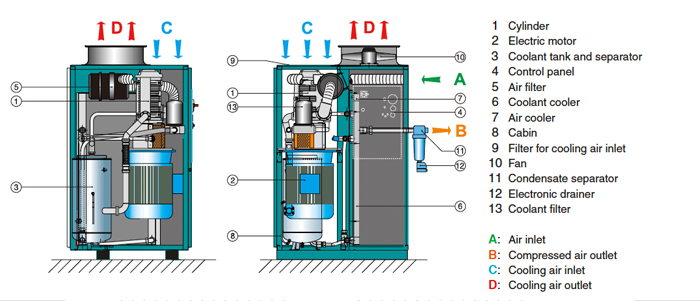

- Intensive coolant injectionfor low compression work and consequent low power consumption.

- Idle runningwith lubrication through suction that reduces the energy requirement to 18% the of installed power.

- High efficiency aluminum coolersguarantee constant performance, also in extreme climate conditions.

- Motor fanfor air-coolant and air-air coolers. The air flow, crossing the cabin, keeps the installed components at low temperature.

- Thermoregulationof the coolant flow towards the cooler, to run in any operating condition.

Vertical Layout

Vertical Layout

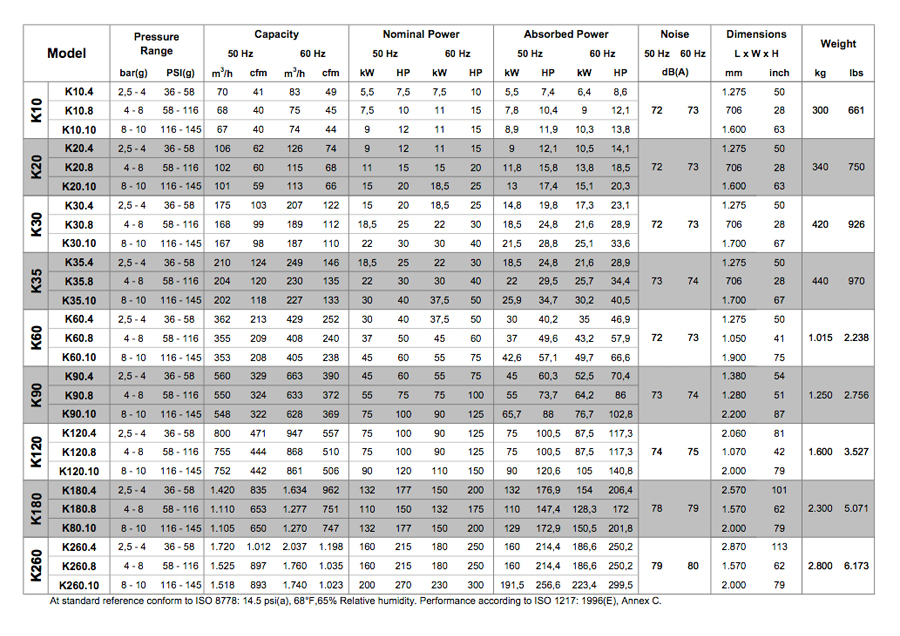

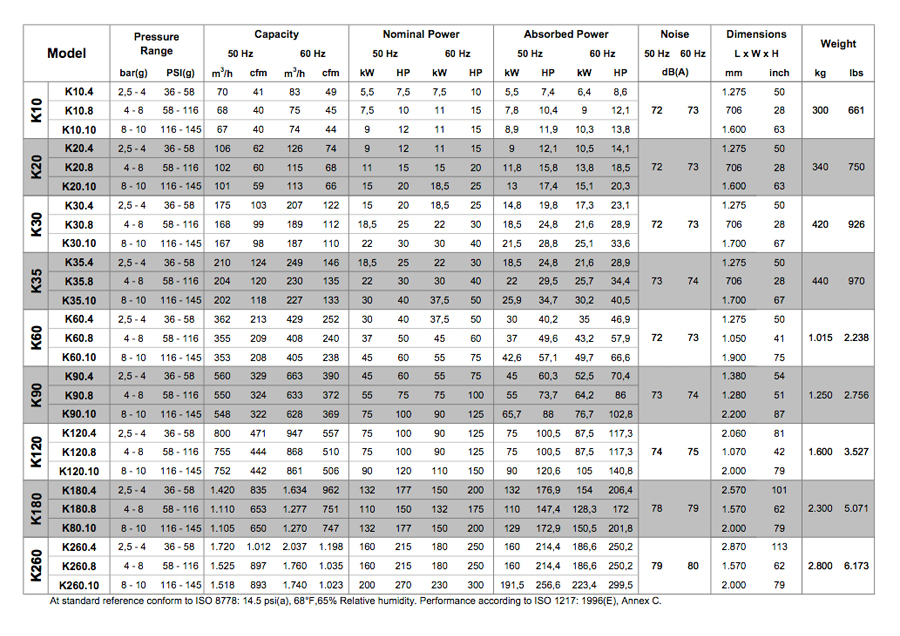

K Series Models

As with all Pneumofore vane compressors, the rotary vane principle and the patented system of intensive oil injection guarantee constant efficiency and air purity over decades of operation. Through fully automatic operation, A compressors adapt to a variety of uses with no compromise to durability.

- Technical note:

- A__.4 version operating pressure range A__.4: 2,5 - 4 bar

- A__.8 version operating pressure range A__.8: 4 - 8 bar

- A__.10 version operating pressure range A__.10: 8 - 10 bar

Components

- “Plug and play” unit, requiring no foundations and fullyequipped for operation: the connection to the electric networkand to the compressed air line are ready for immediate use.

- Coolant separation in 3 phases:centrifugal separation,mechanical trap and final coolant separation through aborosilicate filter element with coolant recovery. The result is aremarkable purity of the compressed air with residual coolantcarry over of 1 mg/m (1 ppm).

- Vertical layoutup to K120 for space economy.

- Soundproof cabin[80 dB(A)] for low noise.

- Removable side panelsfor high accessibility to any machine component, allowing simple, quick and inexpensivemaintenance.

- Filtration cells, easily extractable and washable to keep themachine interior and the coolers clean.

- Cyclone effect air filter, for higher efficiency.

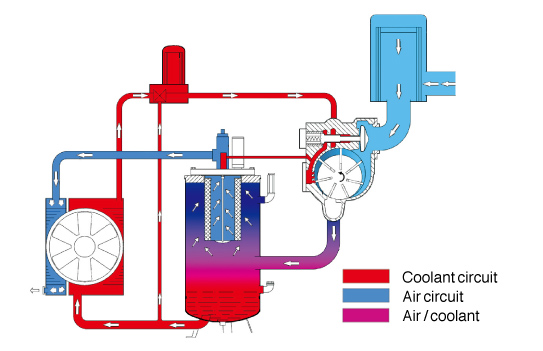

- Electropneumatic control panelto manage operation in bestconditions.

- Hard aluminium alloy vanesfor heavy duty 24 / 7 operation.

- Condensate separatorwith drainer to eliminate compressed air waste.

- Air-end sturdy constructionfor round the clock operation.

- Instruction manual, complete and user-friendly.

- Service diaryto record all maintenance activity.